Product Description

- Magnetic Drum Separators are of self-cleaning type and provide continuous removal of ferrous contamination from a wide range of free-flowing bulk and granular materials in high-volume applications.

- Drums can be ordered with or without housing.

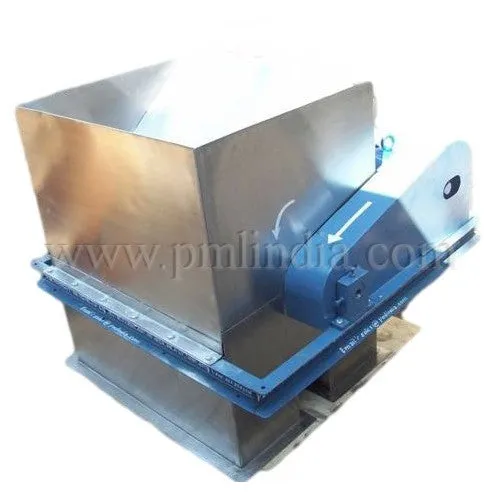

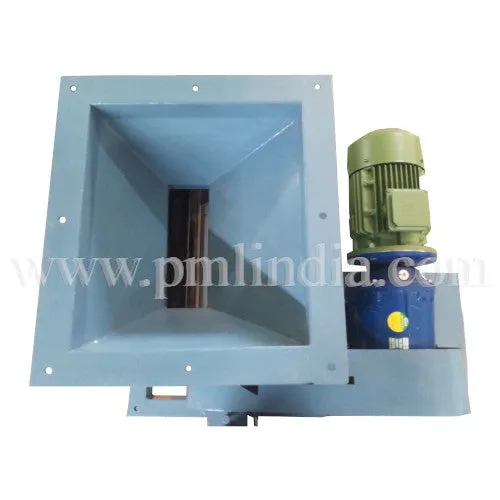

- Magnetic Drum Separator system is a complete machine with Stainless Steel 304 / 316

Housing & Drive system. Only the drum separator unit can also be supplied. - The Drum Separators are available in two types:

High Intensity – (Ndfeb Magnet – 4500 gauss), for Operating Temperature of 80˚C(Max.)

Low Intensity - (Ferrite Magnet - 1200 gauss), for Operating Temperature of 250˚C(Max.) - Ferrous fine particles, nuts, bolts, pins, nails and other tramp metal from free-flowing granular material can be arrested effectively.

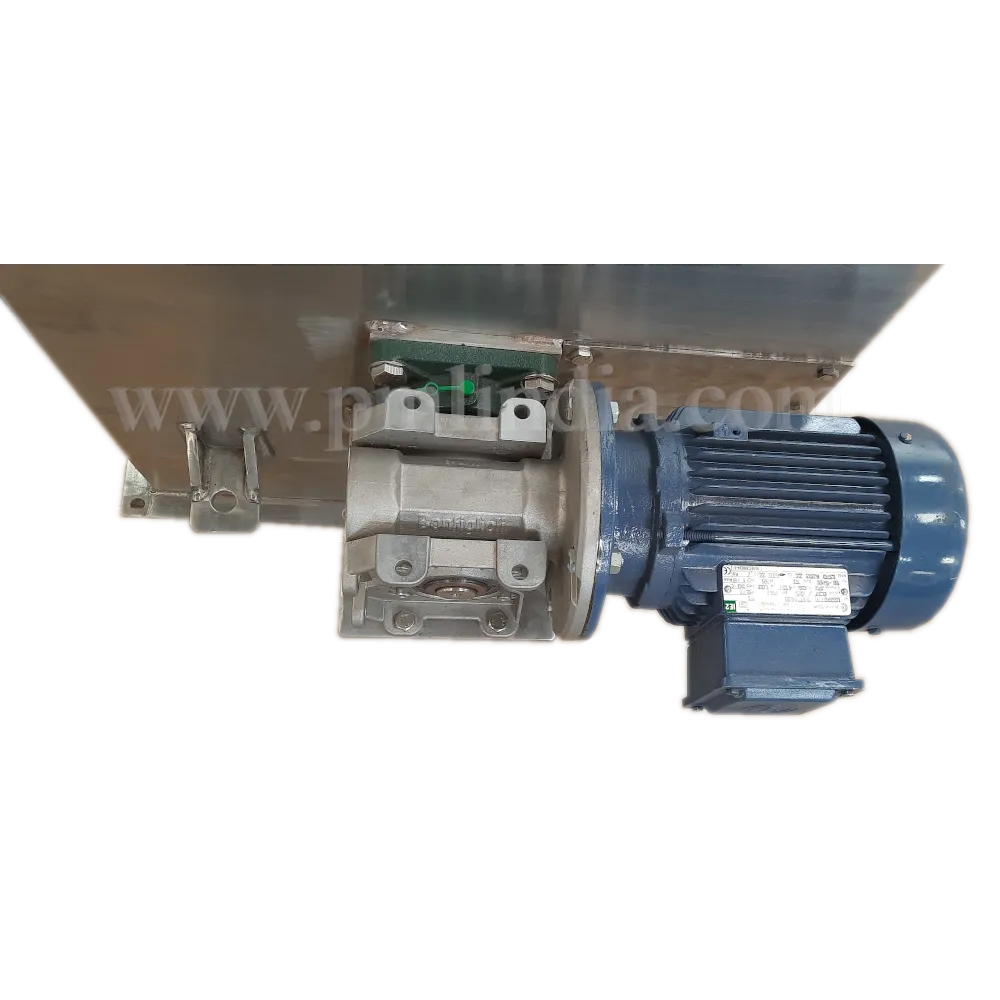

PML IFR Machine at TATA Tea Ltd, Munnar plant

How to use Magnetic Drums?

When material flows onto the drum, a stationary magnetic assembly inside the unit's shell captures tramp metal and holds it securely to the drum's stainless steel surface. With contaminants removed, the good product falls freely to a discharge point. As the drum rotates, cleats sweep the ferrous debris through and out of the magnetic field. The tramp metal is discharged separately, creating continuous self-cleaning separation. PML is drum separator manufacturer in india.

Features:

Magnetic Drums have the following features:

- Designed for continuous separation and self-cleaning. Ideal for high-flow, heavy-contamination applications. It comes with Stainless steel drum and mild steel or stainless steel housings

- Maximum Recovery of Ferrous Metals

- Minimum Maintenance

- They require minimum space and are simple to operate.

- They are flexible enough to be applied for various purposes

Advantages:

- Helps in removing ferrous particles from any nonferrous powder and granules

- Ideal for plastic, food, fertilizer, pharmaceutical, chemical, glass, and continuous process plants

- Provide utmost protection to crushers, grinders, pulverizes, and allied equipment

- Can be used for mining and ore dressing industry

- Eliminate fire hazards and explosions in plants dealing with explosive material.

- Save money, time and labor by reducing break-down time and improving quality.

- The machine can be equipped with PLC & VFD.

Construction:

The magnetic drum separator consists of a rotating drum and stationary drum magnet designed as per the specific needs of the customer. The Drum separator is supplied with the drive system and SS 304/316 housing along with a feed regulating valve.

Standard Magnetic Drum Separators with SS Housing and Drive arrangement:

| Low-Intensity Magnetic Drum Separator (1200 Gauss) suitable for Max. Temperature 250˚ C | |||||

|---|---|---|---|---|---|

| Model No. | Magnets | Max. Temp (ᵒC) | Diameter (mm) | Length (mm) | Gauss Value |

| MDHL1 | Ferrite | 250 | 300 | 300 | 1,200 |

| MDHL2 | Ferrite | 250 | 300 | 450 | 1,200 |

| MDHL3 | Ferrite | 250 | 400 | 600 | 1,200 |

| MDHL4 | Ferrite | 250 | 450 | 750 | 1,200 |

| MDHL5 | Ferrite | 250 | 500 | 1000 | 1,200 |

| High-Intensity Magnetic Drum Separator (4500 Gauss) suitable for Max. Temperature 80˚ C | |||||

|---|---|---|---|---|---|

| Model No. | Magnets | Max. Temp (ᵒC) | Diameter (mm) | Length (mm) | Gauss Value |

| MDHH1 | NdFeB | 80 | 300 | 300 | 4,500 |

| MDHH2 | NdFeB | 80 | 300 | 450 | 4,500 |

| MDHH3 | NdFeB | 80 | 400 | 600 | 4,500 |

| MDHH4 | NdFeB | 80 | 450 | 750 | 4,500 |

| MDHH5 | NdFeB | 80 | 500 | 1000 | 4,500 |

Standard Magnetic Drum without Housing and Drive( Only Drum Separator ):

| Low-Intensity Magnetic Drum Separator (1200 Gauss) suitable for Max. Temperature 250˚ C | |||||

|---|---|---|---|---|---|

| Model No. | Magnets | Max. Temp (ᵒC) | Diameter (mm) | Length (mm) | Gauss Value |

| MDL-1 | Ferrite | 250 | 300 | 300 | 1,200 |

| MDL-2 | Ferrite | 250 | 300 | 450 | 1,200 |

| MDL-3 | Ferrite | 250 | 400 | 600 | 1,200 |

| MDL-4 | Ferrite | 250 | 450 | 750 | 1,200 |

| MDL-5 | Ferrite | 250 | 500 | 1000 | 1,200 |

| High-Intensity Magnetic Drum Separator (4500 Gauss) suitable for Max. Temperature 80˚ C | |||||

|---|---|---|---|---|---|

| Model No. | Magnets | Max. Temp (ᵒC) | Diameter (mm) | Length (mm) | Gauss Value |

| MDH-1 | NdFeB | 80 | 300 | 300 | 4,500 |

| MDH-2 | NdFeB | 80 | 300 | 450 | 4,500 |

| MDH-3 | NdFeB | 80 | 400 | 600 | 4,500 |

| MDH-4 | NdFeB | 80 | 450 | 750 | 4,500 |

| MDH-5 | NdFeB | 80 | 500 | 1000 | 4,500 |

PML also makes custom-designed Magnetic Drum Separators to precisely fit customer’s applications.

The following information is required:

- Type of material from which Iron is to be separated. (Sticky, Granular, Free-flowing, Lumps, etc)

- Size and level/percentage of contamination

- The flow rate of material

- Size/Density of the material particle

Applications:

The Magnetic Drum filters out iron contamination and hence is widely used in all the processing industry for the separation of iron contamination from:

- Minerals and Chemicals

- Food and Flour

- Plastics

- Grains

- Sand

- Fertilizers

- Abrasives

- Glass

- Slag

- Ores

- Rock

- Refractory

Why PML Magnetic Drum Separator?

- 45 years of experience in the design and development of Permanent Magnets and Magnetic Systems.

- Magnet Drum Separators are available in a wide range from 1200 Gauss (up to 250°C) to high intensity 4500 Gauss (up to 80°C).

- Customized Design.

- PML offers comprehensive systems using 2/3 drum separators with other magnetic systems in series to ensure output contamination level to minimum PPM.

- Services such as magnetic calibration/Audit are available.

Some of PML’s Valued customers:

- Ambuja Cements Ltd

- J.K. White Cements Ltd

- Ultratech Cements Ltd

- Sterlite Industries Ltd

- Goa Carbon Ltd

- Trivent Earth Movers Pvt Ltd

- Chettinad Cements Ltd

- Shi Vishnu Cements Ltd

- Gujrat Sidhi Cements Ltd

- Metso Minerals Pvt Ltd

- Kerala Chemicals & Proteins Ltd, Kochi

- Gujrat Fluorochemical Ltd Bharuch

- Praweg Conveyors Thane

- AGI Glasspac Hyderabad

Cart(

Cart(